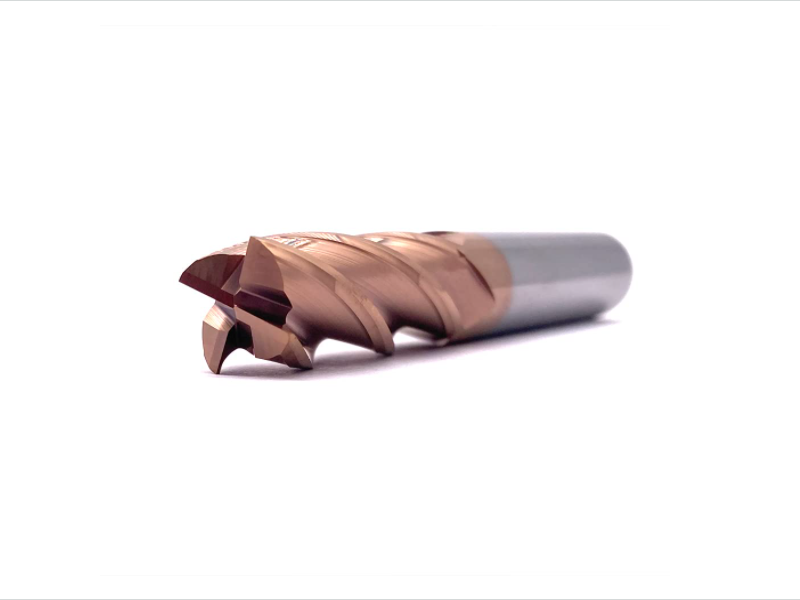

Carbide burrs can be used on many materials. Metals including steel, aluminum and cast iron, all types of wood, acrylics, fiberglass, and plastics. When used on soft metals such as gold, platinum, and silver, carbide burrs are ideal as they will last a long time with no chipping or breaking.

But do you know, what safety guidelines should we follow when using rotary files?

Carbide Burr Usage

Note: This is a guideline only, workers should follow all safety guidelines and safety

standards on the jobsite as provided by the employer. Carbide Burrs are used at

extreme speeds please follow guidelines to help reduce user error and Burr fatigue.

About Pressure when using rotary burr

1. Avoid using so much pressure the grinder speed is reduced – this will cause

overheating and “chipping” of flutes reducing the life of your Burr causing possible

breakage

2.Let the burr do the work and apply only a little pressure

3. Initial contact with the work surface should be light to allow the Burr to “break-in”

4.Do not “tap” or “Chatter” the Burr to the workpiece – this will cause chipping of flutes

or damage to brazing or breakage of the head

5.For long shank Burrs, make sure the Burr is engaged to the workpiece before

spinning to avoid bending the shank

About Movement & Contact when using rotary files

1.Do not Drop the Burr or the grinder with the Burr inserted – this can cause damage to

the carbide causing breakage when applied to workpiece

2.Carbide Burr’s should be stored safely from impact – keep in plastic original container

when not in use

3.Constant movement over the work surface should be maintained –this will keep the

Burr from digging and jabbing into the material causing the Burr to catch and break

4.Do Not “wedge” or jam the Burr into the workpiece – this will cause breakage or

Chipping

5.Maximize the area of contact with the workpiece to improve finish

6.Avoid contact between the workpiece and the shank of the Burr –this can cause tool

to overheat and weaken or even destroy the brazed joint

About Speeds & Overheating when using carbide burr

1. Free run the burr every few minutes to allow the Burr to remain at a cooler

temperature to avoid overheating

2. Maintain a High speed for efficient and economical use of a Carbide Burr

– at high speeds there is less tendency for chips to build in the flute, also the Burr will

cut more freely in corners and pockets, and reduce the chances of jamming, bouncing

or wedging.

If you have any question, please feel free to contact us!

Nanhe Ruixin CARBIDE BURRS