Posted on Oct. 16, 2019

Rotary cutters are used for deburring, welding seams, surface treatments in hard-to-reach places. They are produced in two versions: high speed steel and carbide. The choice of file type depends on the application.

Carbide rotary cutters are designed to work with high-class devices operating at speeds above 15,000 rpm. Can be used to machine most materials up to 67 HRC (Rockwell C). The working part of the file is made of carbide with a hardness of approximately 1500 HV (Vickers). Thanks to the long tradition of carbide production and the cooperation of many specialists, we produce various carbides for rotary cutters of various sizes so that they have optimal properties regardless of the file size.

The working heads of larger carbide rotary cutters are soldered to a hardened steel chuck to a hardness of 46 HRC. The connection created thanks to the unique method is so strong that the company guarantees tool change in the case of desoldering of the head during normal operation. The smaller files are made entirely of carbide.

High speed steel (HSS) cutters are generally intended for machining soft materials such as unhardened steel, bronze, brass etc.

Rotary cutters, due to the cut, can be divided into four main groups: accurate, medium, coarse and very coarse (to which the files belong to aluminum). The basic rule is that for hard materials and when we want a good surface, a small incision should be used. The exception is stainless steel, which requires a thick cut. For soft materials, and when we want to efficiently remove large amounts of material, use a thick cut.

Remember that a small rotary cutter will have a smaller cut than a large cutter belonging to the same group (e.g. M - medium cut). Therefore, in the tables we give not only the group to which the cutter belongs, but also the number of teeth.

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

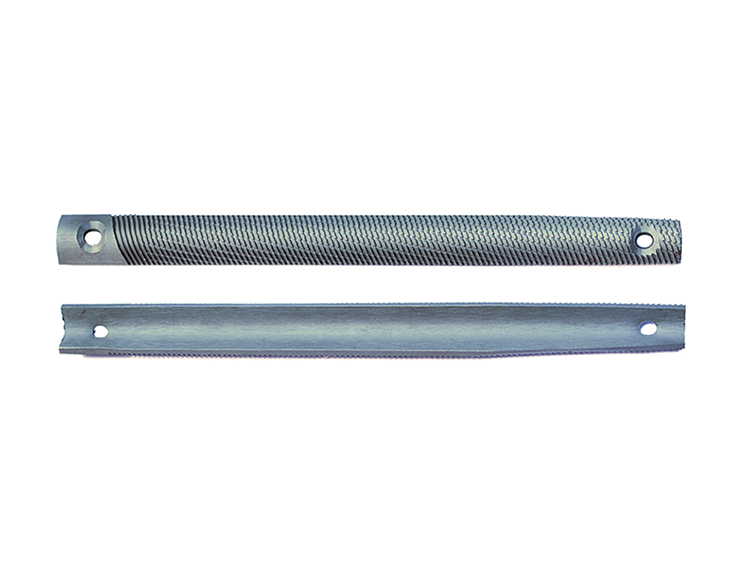

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

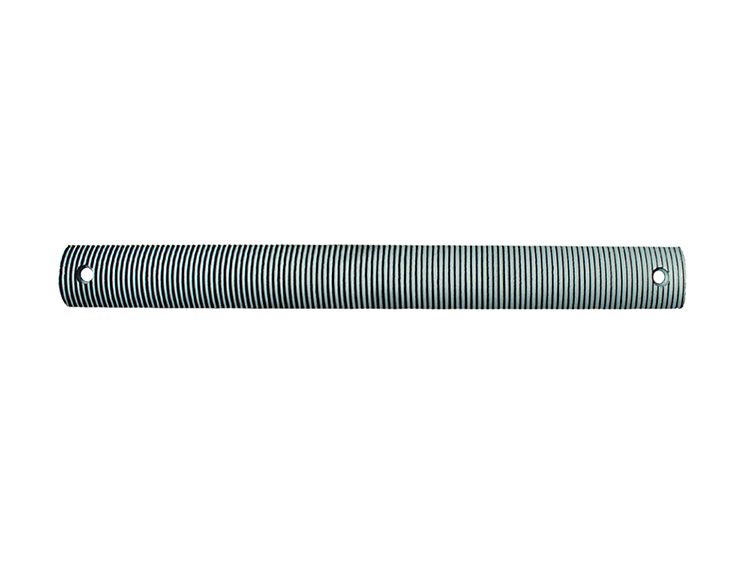

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

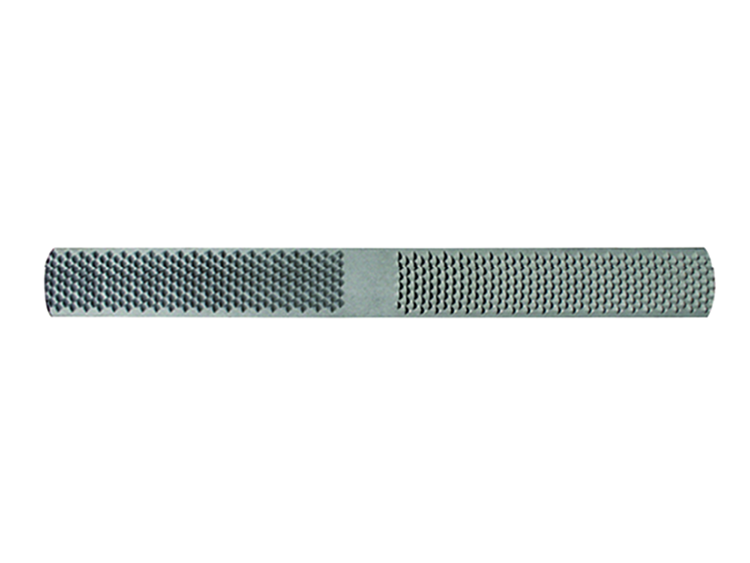

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: