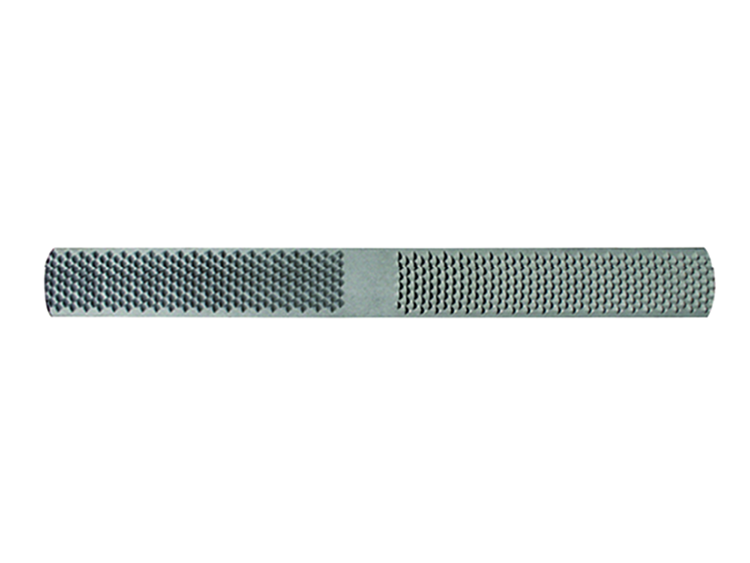

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

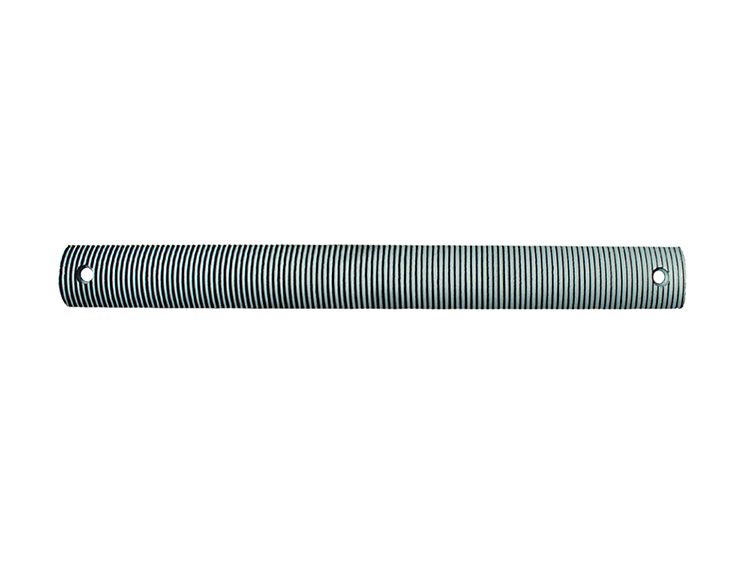

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

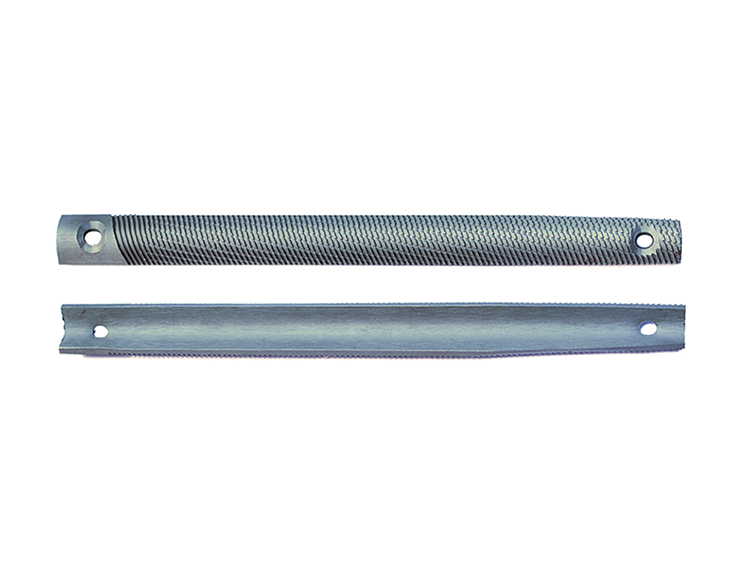

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: