Posted on Dec. 10, 2019

The use of Tungsten Carbide rotary burrs is an effective way to realize mechanization in difficult work operations. Carbide burrs can be widely used for machining Iron, Steel casting, Carbon steel, stainless Steel, Copper, Aluminum, etc. The Aerospace, ship building, automotive manufacturing, machining, and chemical industries commonly utilize rotary burrs for several applications.

Yes!!!

The notch of the burr must correspond to the type of material being processed. The rotational speed must correspond to the diameter of the burr. The shape of the burr, depending on the type of work.

The use of personal protective equipment. Using a tool that provides the necessary characteristics for cutting. Compliance with the recommended speed. Fastening in a collet clip of a borfreza not less than 2/3 of length of a shaft. Uniform pressure on the instrument and constant oscillation. Shock loads are not allowed, the tool is brought smoothly.

1.Follow safety guidelines and safety standards as provided by employer -wear

proper safety equipment such as face shield, hand protection, hearing protection

and lung protection

2. Ensure proper storage of Carbide Burr between usages by using original plastic

container

3.Do not use a “dull” burr this can cause operator to apply more pressure causing

damage to Burr, operator fatigue and damage to workpiece

4.Ensure burr shank is properly inserted into collet and clamped down tightly

5.Ensure work piece is secured tightly and does not move

6.Do not snag or jam your burr into the workpiece

7.No excessive force

8.Avoid contacting shank to workpiece

9.DO NOT drop Burr or Grinder with the Burr in Collet

10.Do not use a Burr with a bent shank

11.Do not “tap” or “chatter” the burr on the workpiece

12.Ensure Maximum power and RPM

Any question from you are welcomed!

Please feel free to contact us!

Nanhe Ruixin Carbide Burr

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

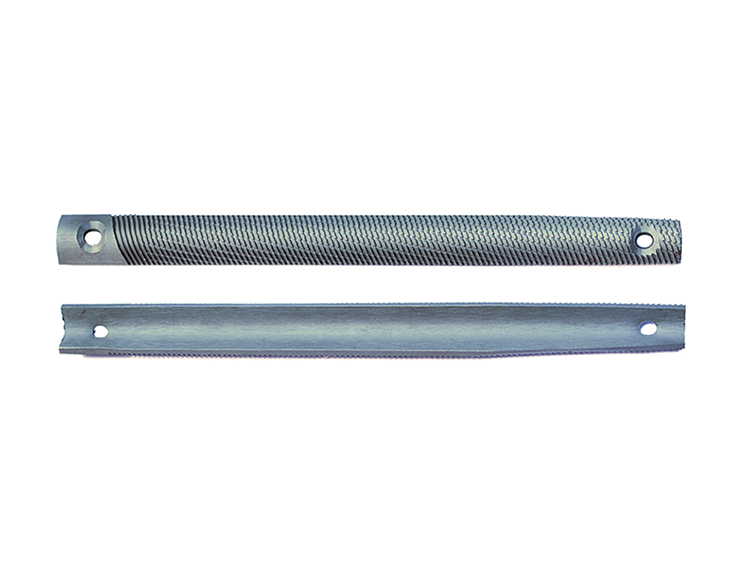

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

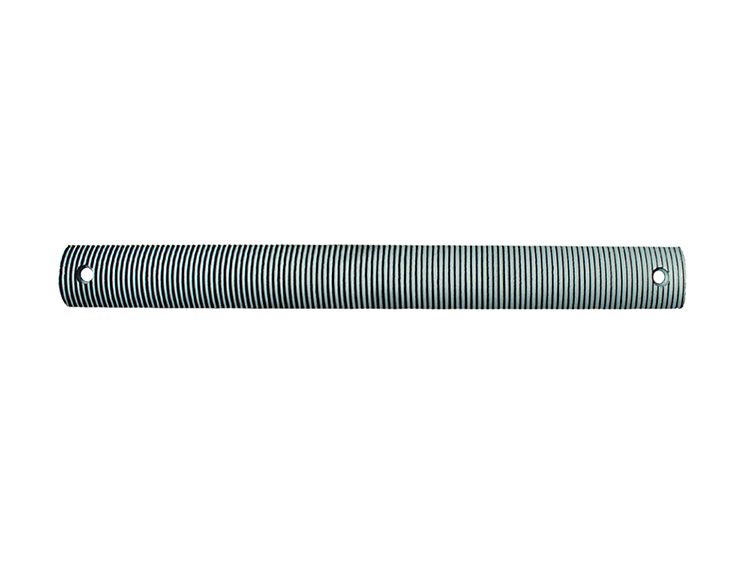

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

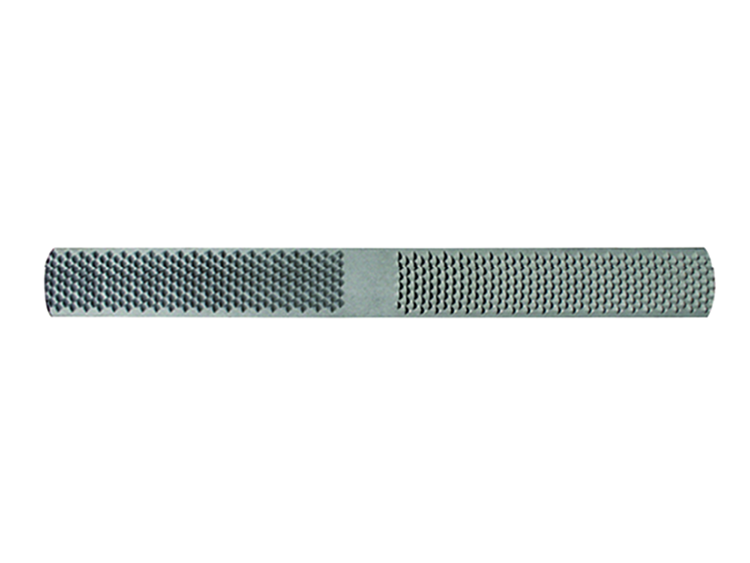

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: