Posted on Dec. 10, 2019

Do you need the Brazing Diamond Tool?Are there any problems when you use them?How much do you know about their materials?Let me give you a brief introduction?

Brazing Diamond tools are increasingly gaining importance as cutting materials for various construction materials. The quality of synthetic diamonds, monocrystalline as well as polycrystalline or CVD-diamonds has been significantly improved over the last years. Integrating these cutting materials requires adequate joining technologies that produce sound joints without exposing the temperature sensitive diamond to too elevated temperatures.

Owing to their covalent atomic bonding diamonds cannot easily be wetted and joined by employing conventional brazing alloys. Hence, active agents are needed to foster an interfacial reaction.

Different active filler concepts are presented and discussed regarding their joint formation. The brazing temperatures influence not only possible diamond degradation but also the interfacial decomposition of the diamond due to the formation of corresponding reaction layers.

Diamonds become increasingly important as a cutting material for the cutting and shaping of metals, in particular reinforced composites, wood and concrete. Nowadays synthetic diamonds are available in two different modifications depending on their individual production route. In the late forties it was a major breakthrough when Percy Bridgeman developed the hightemperature/high-pressure synthesis for artificial diamond. Later this idea had been patented by

General Electric. Since then monocrystalline diamonds (MCD) have been available. A couple of decades later diamond-monocrystals could be sintered to a composite material known as polycrystalline diamond (PCD) which is currently used as cutting bit with defined cutting edges. In the seventies the low-temperature/low-pressure synthesis of diamonds became possible.

Decomposing a carbon-containing gas in a chemical process made the deposition of diamond coating possible. Originally this process has been designed as a coating process for the deposition wear-resistant layers but it is now also possible to deposit free-standing diamond layers that can be integrated in various components and structures utilizing the exceptional properties of diamond.

A key issue regarding the application of diamonds in particular in the tool industry is the joining process. Fabricating reliable joints of high strengths is a key requirement. However, this imposes a large problem on the manufacturer due to the fact that diamonds, no matter whether HT/HP- or CVD-diamond, cannot be joined easily.

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

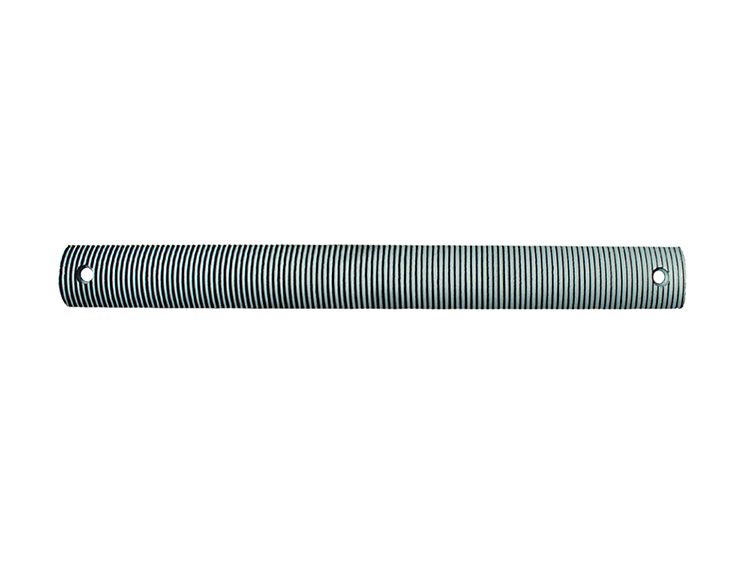

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

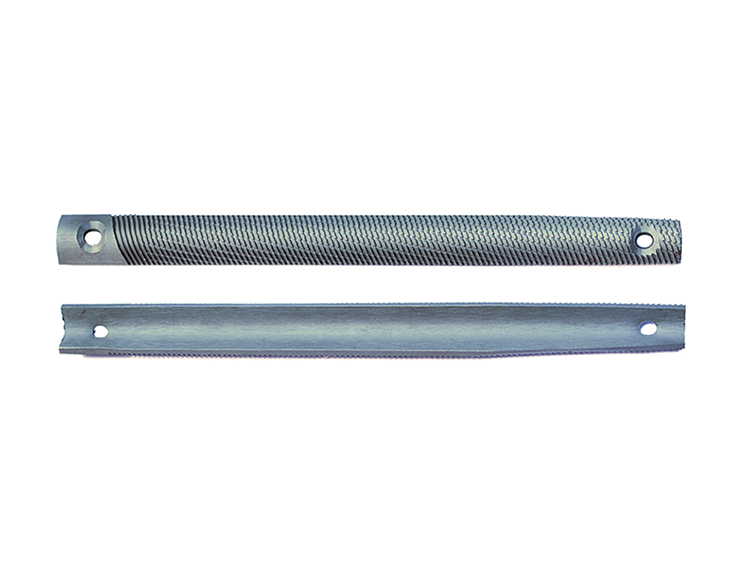

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

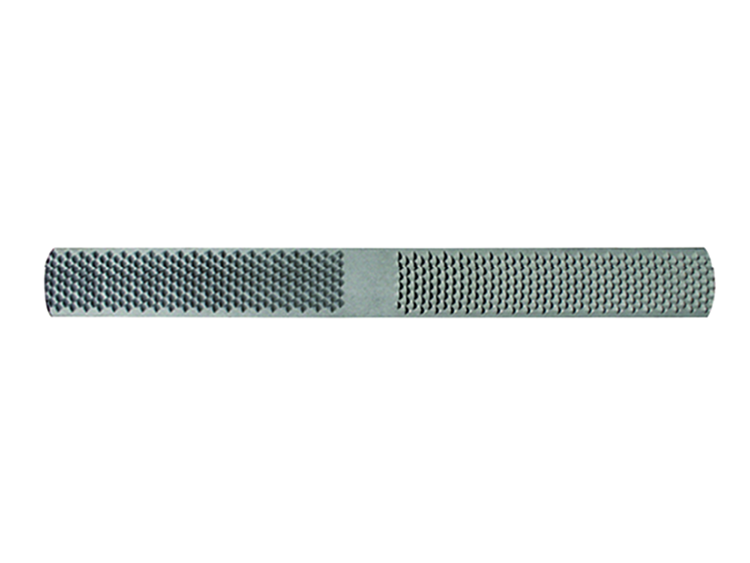

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: